Fiber Film machine film, a unique wrapping film that halves your consumption of film

At Topa we deliver customised packaging solutions. If you wrap more than 15 pallets a day, machine wrapping could be a good choice, though there are various factors to take into account. We would be happy to help you make the right choice.

By optimising your wrapping machine in combination with Fiber Film, you can reduce your CO2 emissions by up to 60% and your film consumption by up to 50%.

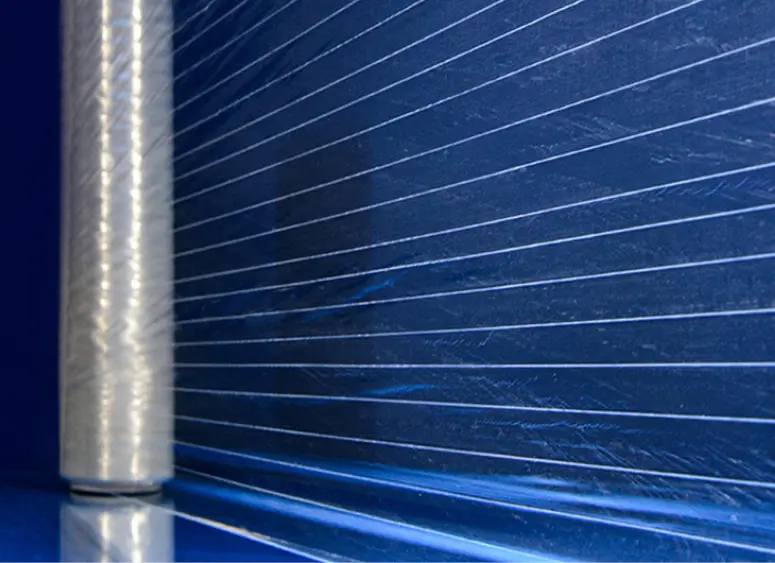

Fiber Film machine film from Topa is a unique, patented wrapping film that halves your consumption of film, and is also so strong that it hardly ever tears. The film is reinforced with thickened fibers that prevent tearing and increase stability. Would you like to test our Fiber Film machine film for yourself?

A unique stretch film

Fiber Film machine films are unique stretch films that are suitable for all kinds of loads. They combine high stretch, high tear-resistance and perfect pallet stability with load security in line with the EU EUMOS 40509-2020 directive.

Less material, meaning less waste

Fiber Film machine film is up to 50% lighter in use than conventional film. This delivers a significant reduction in waste.

Less waste, meaning less CO2

Fiber Film machine film reduces CO2 emissions by at least 50%. This results in a greener footprint. On request, Topa can also handle full compensation for your remaining CO2 emissions for you.

Lower costs

Thanks to the unique composition of Fiber Film machine film, it takes less stretch film to wrap a pallet. This means you pay significantly lower packaging tax. The packaging of pallets using a wrapping machine with Fiber Film is much faster. All in all, this results in up to 30% lower costs per wrapped pallet.

Durable

Thanks to the unique structure of Fiber Film machine film, there is no film breakage during the wrapping process and any damage to the rolls does not cause film breakage either.

Safety and load security

Fiber Film machine film is thinner, lighter, stronger and stretchier than conventional machine film. The film increases the pallet stability in line with the EUMOS 40509 directives. This means that the Fiber Film is more tightly wrapped around the load, resulting in a higher holding force which prevents slipping. Thanks to the right load security, Fiber Film machine film prevents damaged goods and damaged boxes.

Satisfied customers

There are many very satisfied customers already using Fiber Film machine film, including a number of well-known logistics suppliers and production companies.

“Since switching to Fiber Film machine film, our wrapping of pallets has been much more sustainable. We use only half as much film, and wrapping is quicker and cheaper too.”

New Reborn35 Fiber Film

Stronger, more durable & more elastic

At Topa, we focus on sustainable development and technological innovation. We opt for packaging solutions that protect our planet from climate change. With Reborn35 Fiber Film™, we reuse materials, minimize the use of new materials, drastically reduce waste and CO2 emissions, and achieve product circularity.

100% Recyclable

We would be delighted to give you advice on which machine and Fiber Film fit best for you

Through a test carried out at your location and our calculation tool, we can calculate for you which machine and Fiber Film will be best for your situation. Ask about the possibilities for a test at your location.

You can also have your pallets wrapped with Fiber Film machine film tested at our Topa Institute. We can then calculate for you exactly how well your products are protected during transportation, how much film and costs you would save and how much lower your CO2 emissions would be.