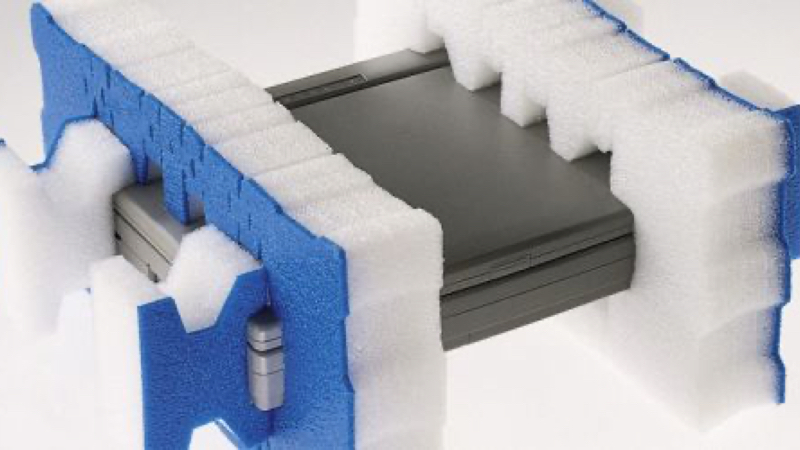

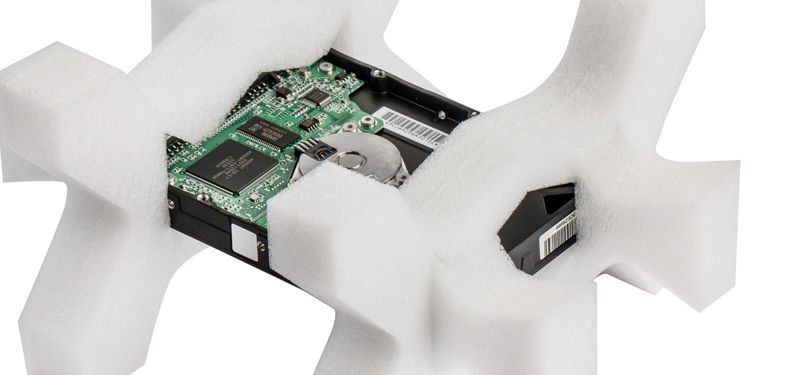

Interior packaging

Interiors make sure that vulnerable or breakable products are not getting damaged by securing them during transport in the package and protect against shocking. Interiors are made of foam, corrugated cardboard or solid board and are designed to your needs. Those materials have different characteristics which are relevant for various products, and the use is determined by the optimal material of the desired performance. The packing is established by combining it with the most suitable materials (composite packaging).

The following materials are specifically used (in combination) for shock cushioning and are often available in different densities, hardnesses and colors which further determine the characteristics.

FOAM

Polystyrene (EPS): the closed cell structure blocks the inclusion of water and has good isolating characteristics. With the first smack it has a good, cushioning function.

Polyethylene (PE or EPE): is the most used polymer and offers the maximum protection for sensitive packed goods. Almost 100% of the impact energy is compensated by an elastic deformation of the material. Each of these materials are availabe in different densities and with various characteristics. PE is recyclable.

Polypropelyne (EPP): is the heaviest to entrust of the plastic foams. The static entrust is very high. It is therefor able to absorb a shock multiple times.

Polyurethane (PU): is easy to change, but is also easy to form. It is usually used for cushioning in packages. An expamle of PU-foam is Instapak.

CORRUGATED CARDBOARD

There can also be buffering mold parts be made from corrugated cardboard. However, the freedom of the form is limited. The material can only absorb a shock once.

HONEYCOMB CARDBOARD

This material is made of honeycomb cardboard and is an effective solution for packing products with a high surface load. Honeycomb cardboard can we used broad, think about inserts such as sheet material or deposit material.

BENEFITS

- Produced in a wide range of foam and corrugated cardboard qualities

- Customized made to your specific wishes and requirements

- Reduction of transport damage, because the primary product is secured during transport

- Less adjustments of outer packagings by using the current packagings sizes with a customized shape

These materials can also be used as corner pieces.