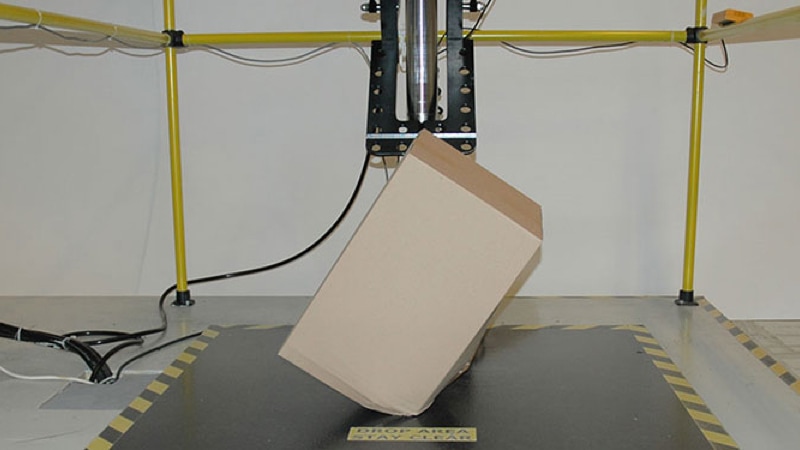

Free fall drop tester

If packages fall during transport, it can cause a lot of damage. By performing a free fall drop test, the protective functioning of the packaging is examined.

This test will demonstrate whether your product is sufficiently protected against shock movements during transport.

Or is the product too well wrapped?

With an optimized packaging, costs can be saved.

General cargo shipment

By means of the free fall drop tester, falling, dropping, and shocking of general cargo during transport is simulated. The goal is to investigate whether the packaging provides sufficient protection for the product. Depending on the weight of the product/packaging combination, the drop height is determined. The package is placed on the table of the free fall drop tester in various ways to precisely determine where the impact of the drop occurs: the top, the short side, long side, corner, rib, etc. A G-value measurement can also be performed during the drop test. Especially for electronic products, it can be interesting to know at which G-value the product will no longer function.

By means of the free fall drop tester, falling, dropping, and shocking of general cargo during transport is simulated. The goal is to investigate whether the packaging provides sufficient protection for the product. Depending on the weight of the product/packaging combination, the drop height is determined. The package is placed on the table of the free fall drop tester in various ways to precisely determine where the impact of the drop occurs: the top, the short side, long side, corner, rib, etc. A G-value measurement can also be performed during the drop test. Especially for electronic products, it can be interesting to know at which G-value the product will no longer function.Various possibilities

Free fall drop tests exist in many ways and can be conducted in accordance with international standards as ISO, ISTA and ASTM and client-specific procedures. Possible international standards are:- All ISTA standards

- ASTM D4169

- ASTM D5276

- ASTM D7386

- ISO 2248

- ISO 4180

Maximum sizes and machine information

Manufacturer: LAB type AD160A- Maximum format test product: 125 x 100 x 100 cm

- Maximum weight test product: 72,5 kg

- Drop height: 300 - 1820 mm

- Calibration interval: annual